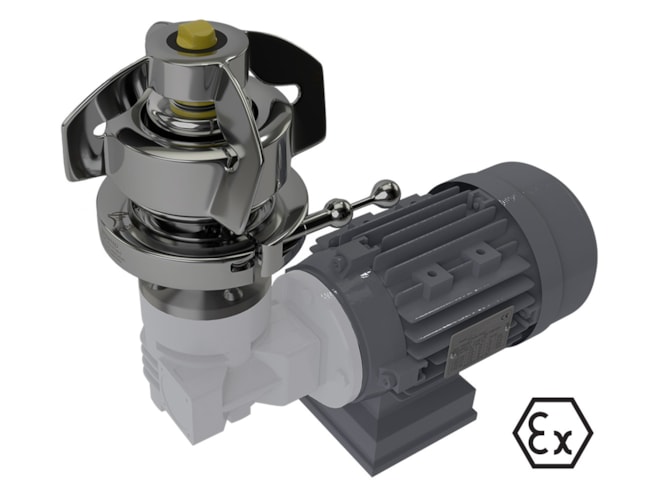

Kest Technology KM ATEX Mixer

Bottom mounted aseptic mixer with 22,000 liter mixing volume, for use in gas and dust environments.

Overview

Features

- 32 to 302F design temperature

- 32 to 275F operating temperature

- -14.5 to 145psi design pressure

- 1-14 pH range

- Up to 22,000L mixing volume

- Ra≤[0.5 μm] [20 µin] polished surface finish

- Revolution counter for secure control of mixing processes

- Heat Certificate 3.1 acc. to EN 10 204

What's in the Box

- Mixer head

- Male bearing

- Tank plate

- Welding tool

- Selected drive unit

Description

Kest Technology KM ATEX Mixer is a bottom mounted magnetic coupled mixer. With its aseptic design, excellent mixing performance and ability to mix to the last drop it has become a popular choice for critical pharma and biotech applications where full product recovery is important. KM ATEX mixer is designed for CIP/SIP applications in ATEX environments and has a Zone 1 and 21 classification for gas & dust environments,

After years of experience developing mixers, the KM ATEX mixer was developed to deliver a perfect mixing result over and over again. KM ATEX mixer is able to mix at low level volumes due to the low building height of the mixer head along with a lot of wing area close to the bottom it can handle continues mixing of low levels. With the fixed position of the wings close to the tank bottom and the possibility to run the mixer during emptying of the tank, which ensures full product recovery and minimized waste.

KM ATEX mixer has a magnetic coupling between the mixing head and drive unit which ensures total integrity of the tank. All tank plates are FEM analyzed according to PED & ASME. This mixer also features zero particle generation due to the robust bearing combination of Zirconium and Sic and the fine-tuned geometry.

To minimize downtime, KM ATEX mixer can be connected with the Kest-Lock system which ensures quick disconnection from the tank plate during maintenance.

Need Help? Call an expert at 1-800-795-6436

We're open Mon - Fri / 8:00 AM - 5:00 PM ET